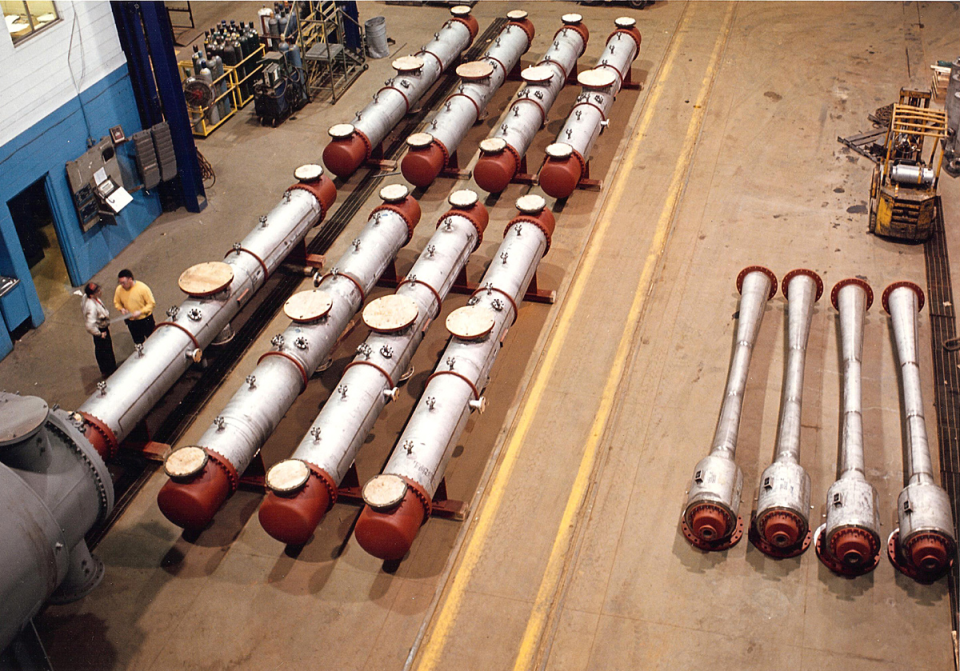

Graham is well versed in vacuum distillation. Our Steam Jet Ejectors and Hybrid Liquid Ring Vacuum Pump packages have been developed using Graham’s 80+ years of experience; we have supplied many hundreds of these systems. Graham products are found throughout the chemical, petrochemical and fertilizer industries. Feedstock plants, producing intermediaries such as ethylene, methanol and ammonia employ our Steam Surface Condensers to reduce the energy required for turbine driven equipment. Downstream secondary petrochemical producing plants, including ethylene oxide/ethylene glycol, styrene, polystyrene, cumene, caprolactam, phenol and ethylene dichloride use Graham Ejectors, Liquid Ring Pump Systems, Steam Surface Condensers, Heliflows® and other Graham Heat Transfer Products.

Petrochemical

Propane Dehydrogenation (PDH)

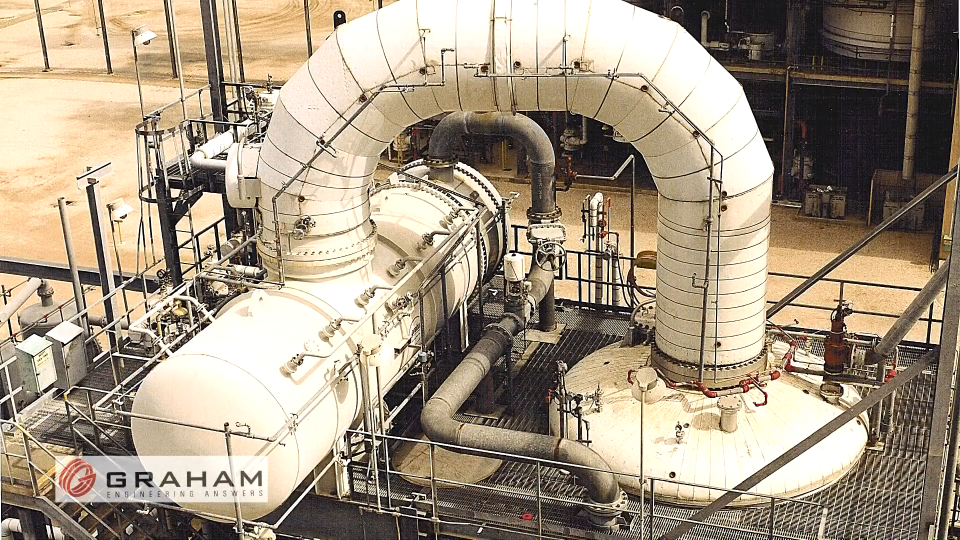

Propane Dehydrogenation (PDH) is made possible in part using Graham specialized Condenser/Reboilers and Reactor Evacuation Ejectors. In this process, propane is converted into propylene, which is the building block for making plastic resins used to make automotive parts, boats & recreational vehicles, appliances, plastic bottles, outdoor furniture and clothing, as well as many other products used every day.

Vacuum Distillation

Graham is expert in vacuum distillation. Our Steam Jet Ejectors and Hybrid Liquid Ring Vacuum Pump packages are designed using Graham’s 80+ years of experience designing many hundreds of these systems. Read more…

Ethylene

Graham Steam Surface Condensers are installed in the largest ethylene producing facilities in the world. Product reliability and the engineering capability to effectively integrate Steam Surface Condensers into today’s world scale facilities make Graham an ideal partner. Graham has proven experience with cracked gas compressors, ethylene and propane refrigeration compressors, and other equipment.

Methanol

Production of this building block petrochemical requires a number of steam driven turbines for compressor services. Graham Steam Surface Condensers and Condenser Venting Packages are used to conserve energy. The largest single train methanol plants located in the Middle East use Graham Steam Surface Condensers. Synthetic gas compressors are key to throughput, and Graham Surface Condensers are the preferred choice.

Ammonia/Urea

Fertilizer production to support the world’s growing population requires reliable and proven designs of Steam Surface Condensers and Ejector Systems. Graham has installations throughout the world in plants designed by every major ammonia and urea Process Licensor. Our equipment is known for its reliability, quality and the engineering expertise that goes into the design of every product we manufacture.