At Graham we provide an optimized solution to meet our customer’s needs – whether that be a hybrid ejector, condenser, and liquid ring vacuum package to minimize utility consumption and provide operational flexibility or a single stage ejector to reduce initial capital cost.

Engineering Capabilities

Meeting Customer Needs

Graham uses our in house developed equipment sizing software to quickly evaluate the process data and desired materials of construction provided by our customers and establish an initial equipment arrangement. Further optimization is then achieved by additional iterations. Decades of experience in sizing equipment has been programmed into this software, providing Graham engineers the ability to quickly iterate multiple solutions depending on our customer’s needs, from the FEED stage through placing an order.

Project Engineering

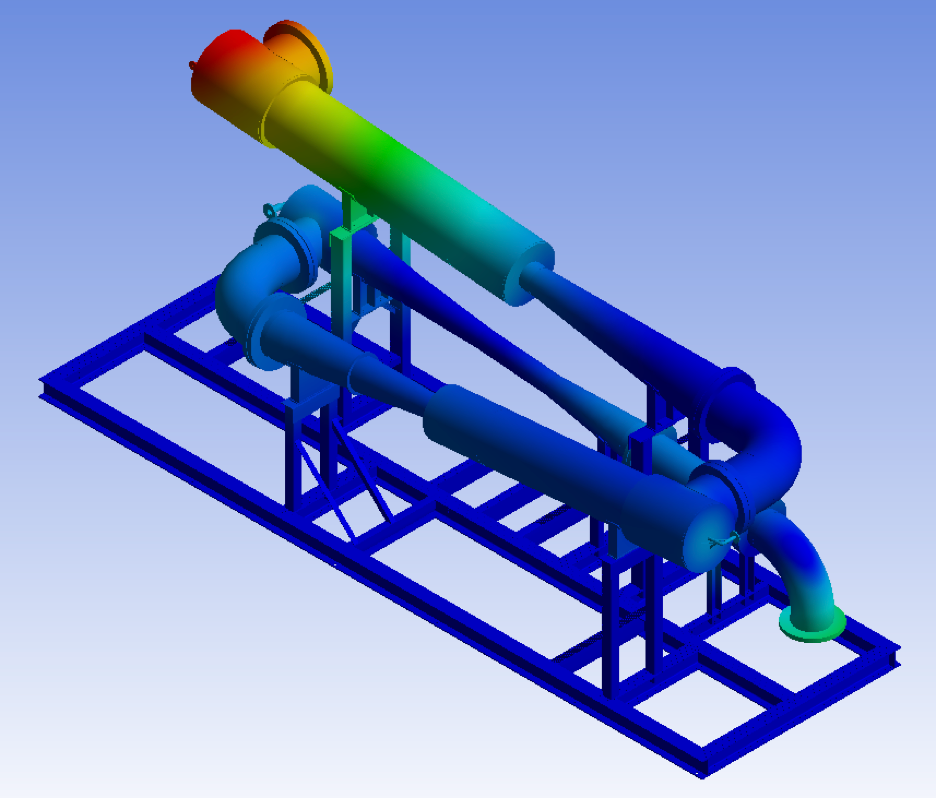

Upon receipt of a customer order, a Project Engineering team is assigned to thoroughly review all contract documentation to ensure compliance. Once the team is sure that all requirements are documented and understood, the detailed hydraulic, thermal, and mechanical design is completed so that accurate general arrangement drawings and mechanical calculations may be provided to the customer for review. Our parametric modelling software allows the engineering team to quickly accommodate the majority of requested changes to the design to allow a seamless transition to creating the documentation required to purchase material and begin fabrication.

Code and Standards Compliance

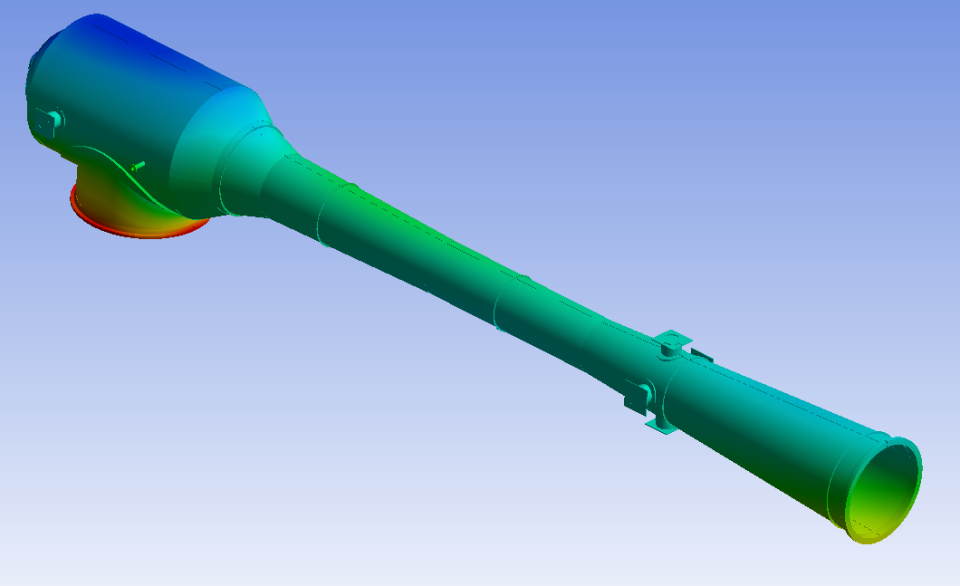

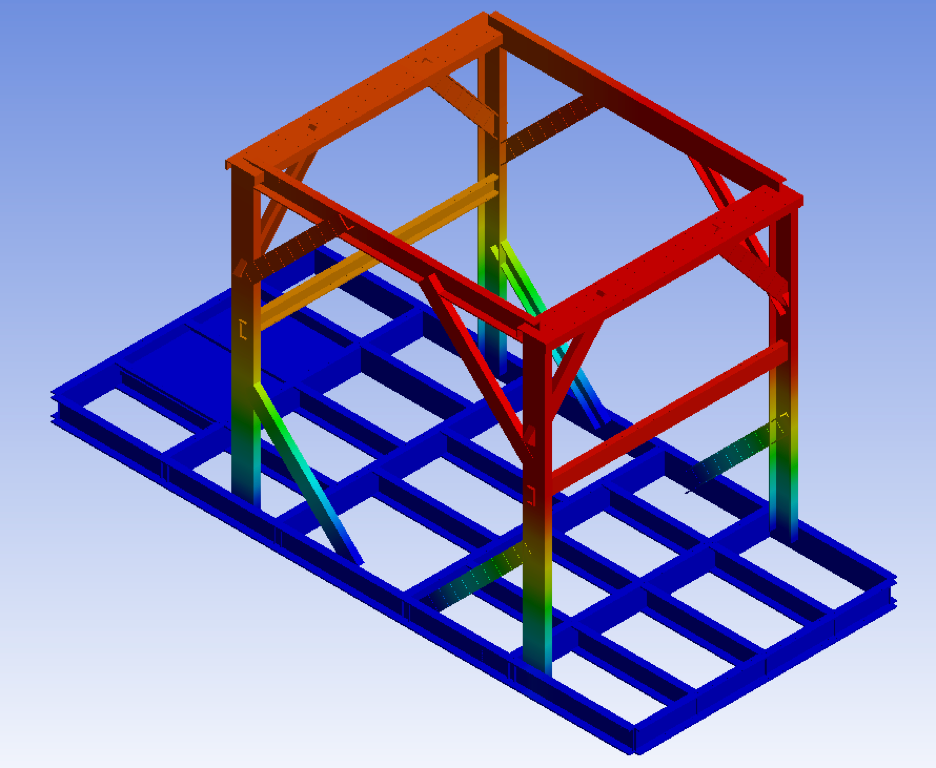

Graham is capable of working and complying with the Codes and standards listed below, and also have the in-house capability to perform Finite Element Analysis for instances where the stated standards do not have a developed analysis method for external loadings applied to our equipment.

- ASME Section VIII, Division 1

- ASME B31.1 / B31.3

- ASME PCC-1 / PCC-2

- HEI Standards

- API-660 / 681 / 682 / TR 938-C

- TEMA

- International standards PED / PE(S)R / DOSH / KOSH / Korean Gas Safety

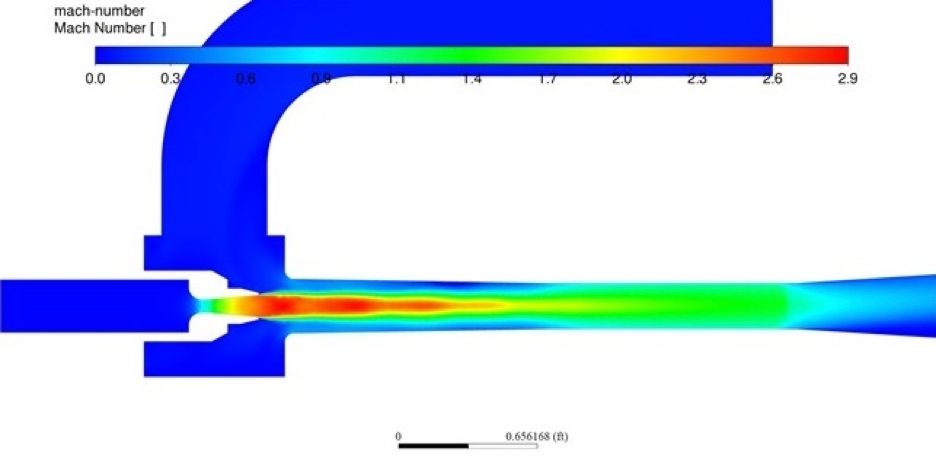

Research and Development

Graham’s Research and Development Department is focused on efforts to improve efficiency and pass the energy saving benefits along to our customers. Their engineers pull from decades of historical data to ensure the legacy of quality and reliability is maintained while moving into the future. The team uses CFD to further advance the company’s understanding of the complex fluid dynamics, which allows our equipment to work day in and day out for years on end. This improved understanding of fluid flow coupled with our experience in thermodynamics, chemical interactions, and process control; further augments Graham engineers experience in Aerospace, Chemical, and Mechanical Engineering. This results in measurable energy consumption reduction being passed along to our customers.